Excavator Basic Operations

Excavators are indispensable machines across multiple industries, recognized for their ability to handle demanding tasks with speed and accuracy. Their core operations involve the coordinated movement of the boom, arm, and bucket through advanced hydraulic systems. These functions allow operators to dig, lift, load, and move soil or other materials efficiently.

In construction, excavators are used to prepare building foundations, handle demolition, and transport heavy debris. In agriculture, they play a role in irrigation, land clearing, and ditch construction. Landscapers use them to shape terrain, create water features, or install retaining walls. Road maintenance jobs also depend heavily on excavators for repairing pavement, digging drainage ditches, and preparing surfaces.

Excavator Finishing Work

Excavators are essential for finishing work, such as leveling land and digging trenches. These tasks ensure smooth surfaces for foundations, effective drainage systems, and precise preparation for roads and utilities.

Excavator Safety Operations

Always wear protective gear, maintain clear visibility, follow weight limits, and conduct inspections before operating an excavator.

Why Continue Reading

Understanding excavator operations unlocks efficiency, safety, and productivity across multiple industries.

How to Operate a Mini Excavator

Learning to operate a mini excavator begins with a thorough pre-operation check. Operators must inspect fluid levels, hydraulic hoses, tracks, and attachments before starting the machine. Once the safety inspection is complete, the operator enters the cab and secures the seat belt. Starting the engine involves engaging the ignition and activating the hydraulic unlock switch.

Modern excavators, including Kubota mini excavator models, often feature intuitive joysticks: the left joystick typically controls swing and boom movement, while the right joystick manages the arm and bucket. By coordinating these controls, the operator can dig, lift, and place soil or materials with precision.

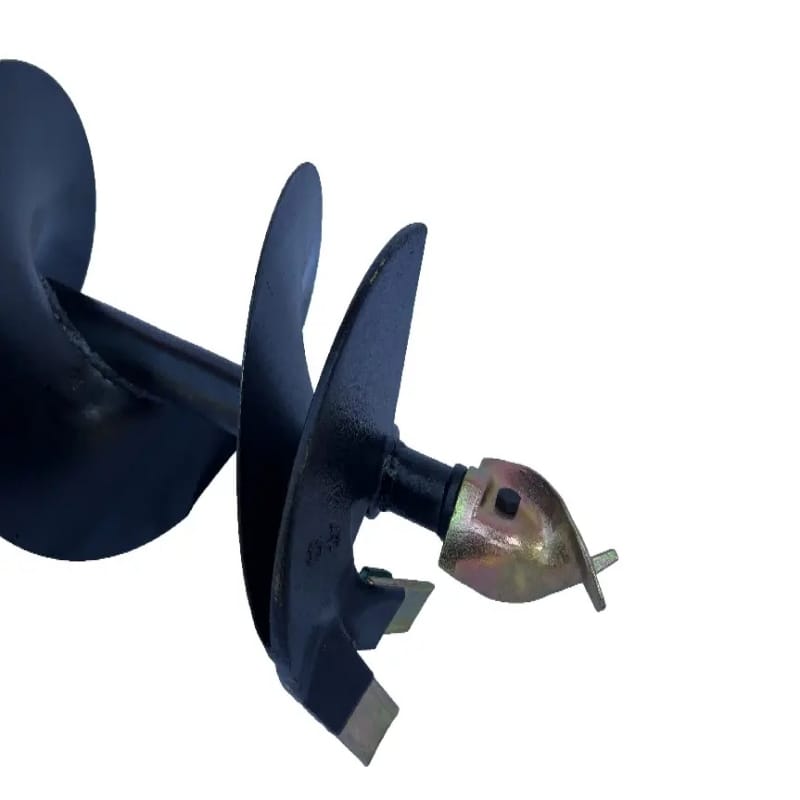

Chinese mini excavator manufacturers like Ningbo ACE Machinery design machines with responsive hydraulics and ergonomic controls, making them suitable for both beginners and professionals. Practice in an open area helps new operators gain confidence with smooth and steady movements. Attachments such as augers, hammers, or rippers can also be added, extending the machine’s ability to perform drilling, demolition, or specialized tasks. Understanding these basic operations allows contractors and homeowners alike to maximize the machine’s potential while maintaining safe practices.

How to Use a Mini Excavator

Using a mini excavator effectively requires matching the machine to the job at hand. For trenching, the operator positions the tracks along the trench line and uses the bucket to scoop soil systematically. For grading, a blade or grading bucket attachment may be installed to smooth out surfaces, ensuring even preparation for foundations, roads, or landscaping projects.

Mini excavator attachments provide additional versatility, allowing the machine to break concrete, compact soil, or drill holes. This adaptability makes compact machines especially valuable on smaller job sites where space is limited but productivity must remain high.

Road maintenance jobs are a prime example of this flexibility. Mini excavators can repair curbs, dig for drainage pipes, or clear damaged asphalt. Kubota mini excavator models are widely recognized for their compact size, fuel efficiency, and reliability, while Chinese mini excavators are appreciated for their strong balance between price and performance.

Proper operation involves careful attention to machine stability, awareness of surroundings, and consistent monitoring of digging depth. When used correctly, mini excavators reduce labor time, improve accuracy, and enhance overall project efficiency.

How Much Does a Mini Excavator Weigh

The weight of a mini excavator is an important factor to consider when selecting equipment. Smaller models, often designed for residential or light construction projects, may weigh around 1 to 2 tons. These lightweight models are easy to transport and maneuver in tight spaces.

Larger compact models, suited for heavier construction or road maintenance jobs, may weigh between 3 to 5 tons. The additional weight provides better stability, increased digging force, and the ability to handle larger attachments.

Kubota mini excavator models are engineered with optimized weight distribution, ensuring balance and safety during operations. Similarly, Chinese mini excavator designs emphasize portability, with models that can be easily moved on trailers from one site to another. Contractors must also consider how weight affects ground pressure. Lighter excavators are ideal for delicate landscaping or soft terrain, while heavier models perform better in rugged environments.

Weight also influences fuel consumption, operating efficiency, and lifting capacity. Understanding these differences allows operators to choose the right machine for each project, ensuring safe and productive use in both urban and rural applications.

Summary

Mini excavators deliver reliability, safety, and versatility for construction, landscaping, and road projects.